Why Impedance Control Is Required For PCB

Published on 1/25/2019 2:57:10 PM

Description

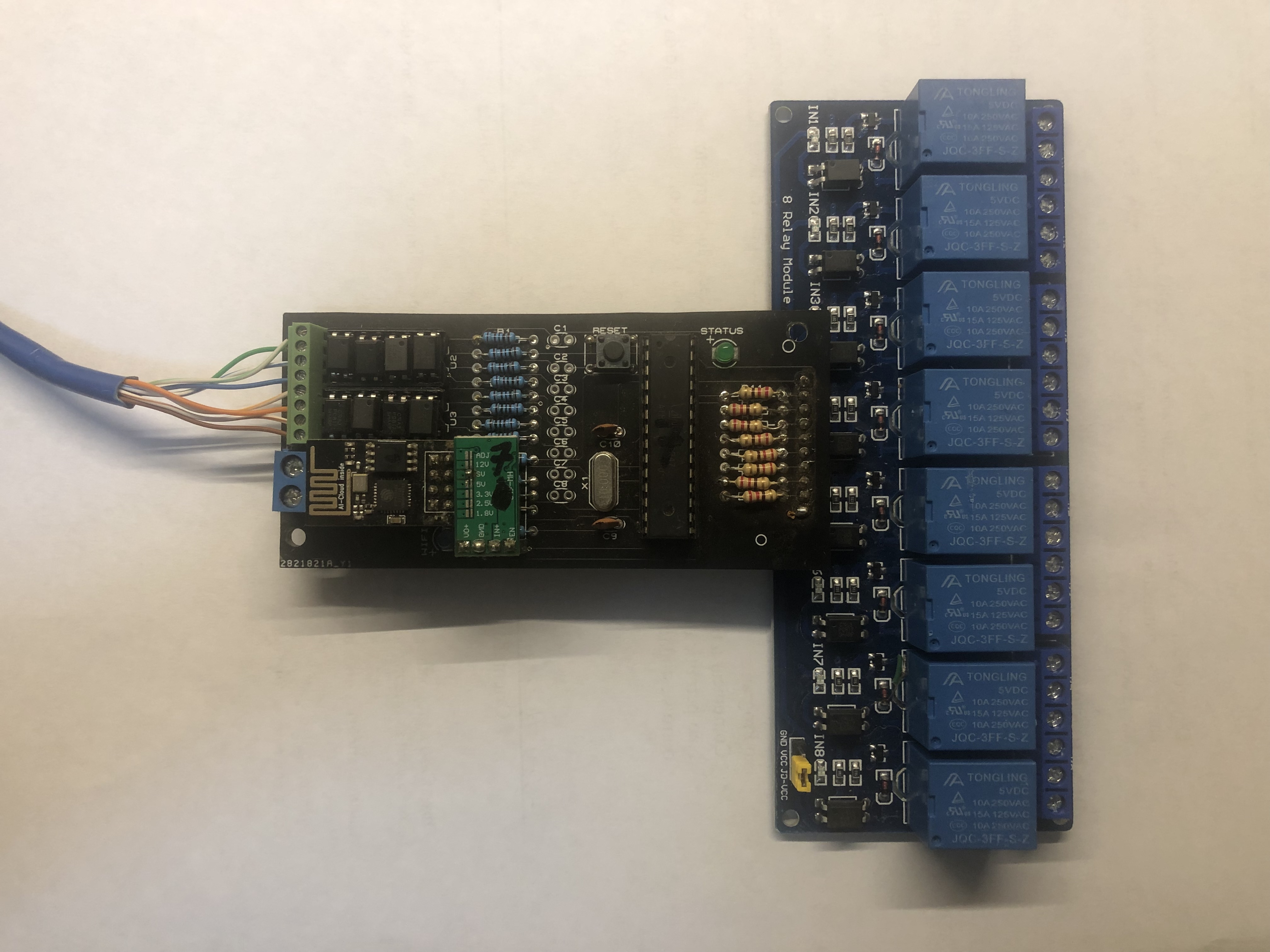

<p><span style="display:none;"></span><span style="font-family:"font-size:16px;">Before we talk about the</span><strong><span style="font-family:"font-size:16px;"> impedance control</span></strong><span style="font-family:"font-size:16px;">, let’s see how Wikipedia explains about this: Impedance control is an approach to the control of dynamic interaction between a manipulator and its environment. This type of control is suitable for environment interaction and object manipulation. Therefore, impedance control is required for some specific </span><span style="font-family:"font-size:16px;">printed circuit boards</span><span style="font-family:"font-size:16px;">.</span><br/><br/><span style="font-family:"font-size:16px;"> 1. For PCBs that need </span><a href="https://www.allpcb.com/soldering_thru-hole_component.html" target="_blank"><span style="font-family:"font-size:16px;">through holes component parts</span></a><span style="font-family:"font-size:16px;">, once the parts are soldered, consider about the electrical conductivity and signal transmission performance ect., the lower the impedance control value is, the better. The resistivity should be no more than 1×10-6 square centimeters;</span><br/><br/><span style="font-family:"font-size:16px;"></span><span style="font-family:"font-size:16px;">2. During the PCB fabrication process, the boards will experience with plating, hot air leveling and many other process, we have to make sure all the materials used are resistivity guaranteed, therefore to achieve the PCB quality requirement and the PCBs are well performed during actual use;</span><br/><br/></p><p style="text-align: center;"><img src="https://file.allpcb.com/bbs/19/01/25/143855095.jpg" alt="pcb fabrication process"/> </p><p><br/><span style="font-family:"font-size:16px;"> 3. </span><strong><span style="font-family:"font-size:16px;">Hot air leveling</span></strong><span style="font-family:"font-size:16px;"> is the essential one during the whole process, and it critical for impedance control. The biggest defective for chemical tin plating is its allochroic-friendly ( it is easy to oxidized or resolves in water), poor solderability features, these make it difficult to assemble the boards, and the high impedance value contributes to poor electrical conductive, or unstable performance of boards;</span><br/><br/><span style="font-family:"font-size:16px;"> 4. There are various </span><strong><span style="font-family:"font-size:16px;">signal transmission</span></strong><span style="font-family:"font-size:16px;"> in printed circuit boards, we have to improve the frequency if we require to improve the transmission speed. While the etching, stack-up thickness, trace width will affect the impedance value, and cause distorted signal, thus influence the PCB use. Therefore, we have to control the impedance value in to a certain value;</span><br/><br/><span style="font-family:"font-size:16px;"> All in all, the impedance control will affect the actual performance of PCBs, in order to guarantee the PCB quality, impedance control is highly recommended for the design.</span><span style="font-family:"font-size:16px;"> </span></p>

46

comment

All comments

Unknown

Unknown

3644

0

46

Rules about cashback: 1. Valid time: ALLPCB cashback activity will end on April 1st. 2. Capped amount: The capped amount of cashback for each account is $5,000. Each order can get a maximum of $2,000 cashback. That means every author can get $5,000 max. 3. Cashback range: The cashback activity only covers the corresponding PCB order. The order amount for other combined payment products will be invalid. 4. Clicking your own promotional link will be invalid. The same email address, shipping address, contact information, and phone number are all recognized as the same account. 5. ALLPCB has the final interpretation right of the cashback activity.

ALLPCB will donate 2% to the author for this promotion link.