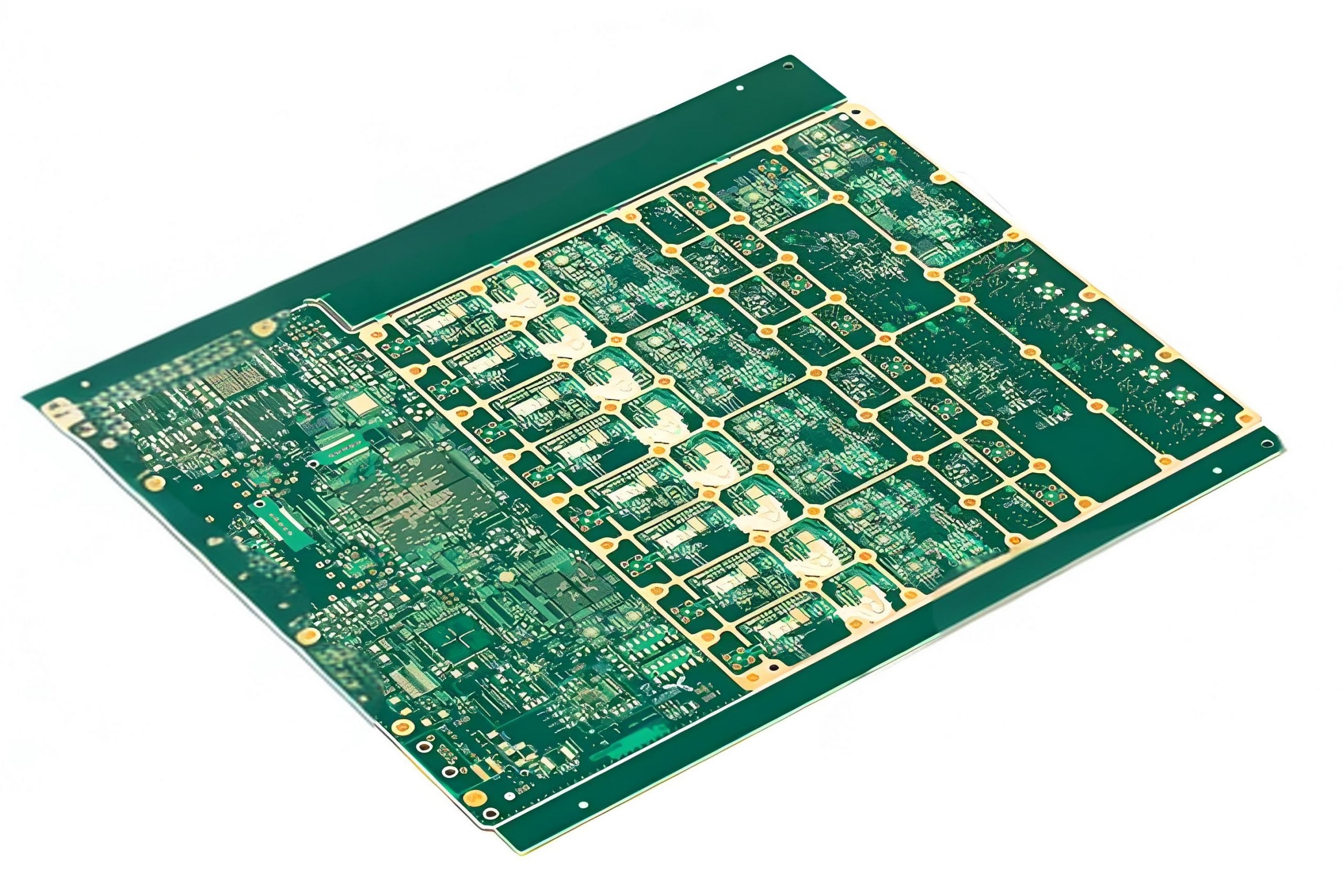

In the world of electronics, Printed Circuit Boards (PCBs) are the backbone of nearly every device. Ensuring their cleanliness during manufacturing is crucial for optimal performance and reliability. At ALLPCB, we understand that effective PCB cleaning is a key step toward achieving manufacturing excellence. Whether you're dealing with flux residues, dust, or other contaminants, proper cleaning methods can enhance electronic performance and extend the lifespan of your boards.

In this comprehensive guide, we'll explore why PCB cleaning matters, the best methods to achieve a clear board, and how it contributes to superior manufacturing outcomes. Let’s dive into the details of maintaining clean PCBs for top-tier electronic performance.

Why PCB Cleaning is Essential for Manufacturing Excellence

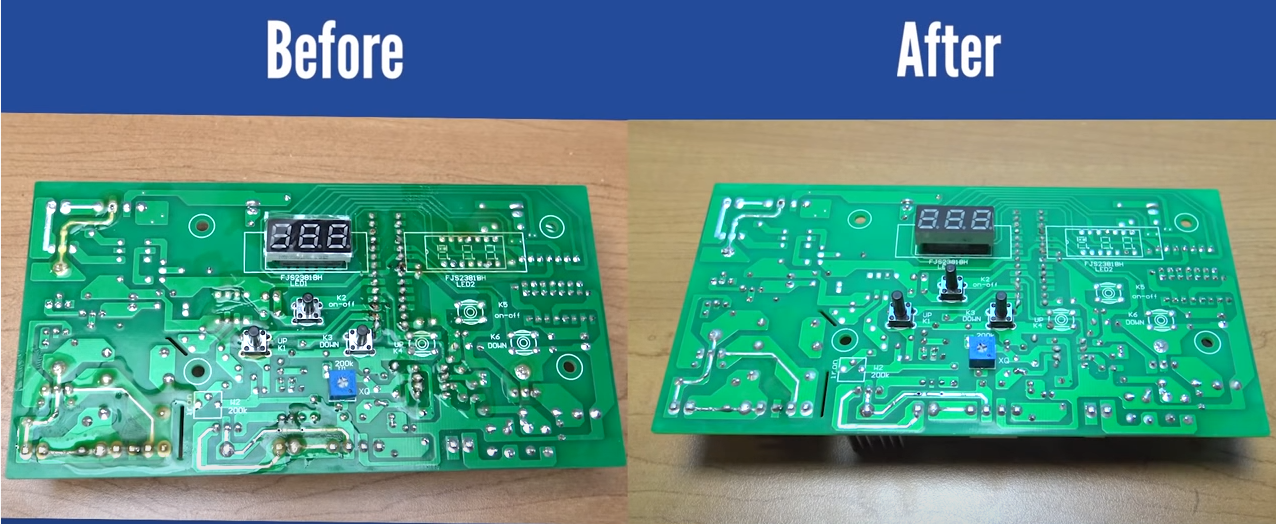

Clean PCBs are not just about aesthetics; they directly impact the functionality and durability of electronic products. During manufacturing, PCBs can accumulate residues like flux, solder paste, dust, and even fingerprints. If left uncleaned, these contaminants can lead to issues such as short circuits, corrosion, or signal interference, ultimately affecting performance.

For instance, flux residues, often left after soldering, can attract moisture over time, leading to corrosion of metal components. According to industry studies, up to 30% of PCB failures can be attributed to contamination-related issues. By prioritizing cleaning, manufacturers can reduce failure rates, improve signal integrity (ensuring impedance values remain within the typical range of 50-100 ohms for high-speed designs), and meet stringent quality standards.

The Impact of Contaminants on Electronic Performance

Contaminants on PCBs can disrupt electronic performance in several ways. Ionic residues, such as salts from flux, can create conductive paths, leading to short circuits. Non-ionic residues, like oils or grease, can interfere with conformal coating adhesion, leaving the board vulnerable to environmental damage.

In high-frequency applications, even small amounts of residue can alter signal speeds, which are critical for maintaining performance (often measured in gigabits per second for modern designs). For example, a study in electronics manufacturing showed that uncleaned boards had a 15% higher rate of signal degradation compared to properly cleaned ones. This makes cleaning not just a step in the process but a cornerstone of reliable performance.

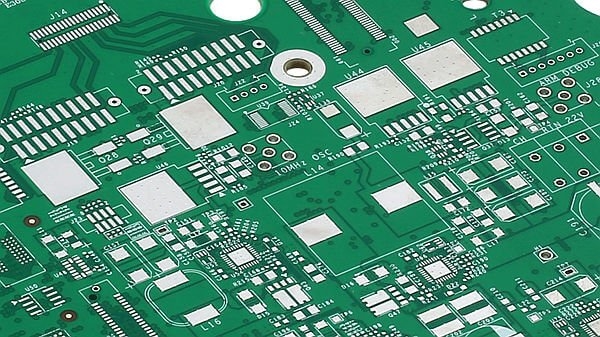

Common Contaminants in PCB Manufacturing

Before diving into cleaning methods, it’s important to understand the types of contaminants that PCBs encounter during manufacturing:

- Flux Residues: Left after soldering, these sticky substances can attract dust and moisture.

- Solder Paste: Excess paste can harden and create unwanted conductive paths.

- Dust and Debris: Particles from the manufacturing environment can settle on boards, affecting component placement.

- Fingerprints and Oils: Human handling can leave oils that interfere with soldering or coating.

- Corrosion Products: Oxidation on metal surfaces can form if boards are exposed to humidity.

Each of these contaminants requires specific cleaning approaches to ensure a clear board ready for assembly and use.

Effective PCB Cleaning Methods for Optimal Results

There are several proven methods to clean PCBs during manufacturing. The choice of method depends on the type of contaminant, the stage of production, and the sensitivity of the components. Below, we outline the most effective techniques to achieve a clear board and boost manufacturing excellence.

1. Manual Cleaning with Isopropyl Alcohol

Manual cleaning is a straightforward and cost-effective method for small-scale production or spot cleaning. Using isopropyl alcohol (IPA) with a concentration of 70-99% and a soft brush or cotton swab, manufacturers can remove flux residues and light contaminants from specific areas of the PCB.

How to Do It: Dip the brush or swab in IPA, gently scrub the contaminated area, and wipe it dry with a lint-free cloth. This method works well for accessible areas but may not be practical for large-scale operations or intricate designs with tight spaces.

2. Ultrasonic Cleaning for Deep Contamination Removal

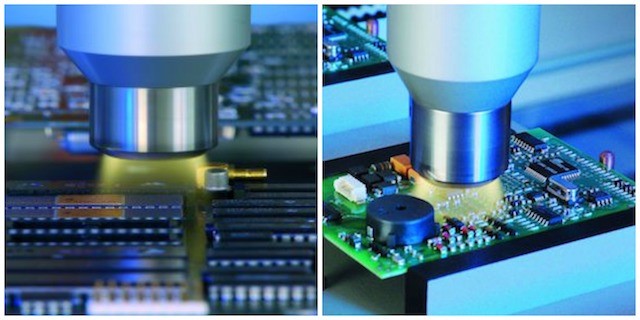

Ultrasonic cleaning uses high-frequency sound waves to agitate a cleaning solution, effectively dislodging contaminants from hard-to-reach areas. This method is ideal for removing stubborn flux residues and dust from complex PCB layouts.

How It Works: The PCB is placed in a tank filled with a cleaning solution (often a water-based detergent or solvent). Ultrasonic waves create tiny bubbles that implode, generating a scrubbing action that cleans the board without physical contact. Typical frequencies range from 20 to 40 kHz, ensuring thorough cleaning without damaging delicate components.

Caution: Not all components can withstand ultrasonic cleaning. Sensitive parts like MEMS sensors or certain capacitors may require alternative methods.

3. Aqueous Cleaning for Eco-Friendly Solutions

Aqueous cleaning uses water-based solutions to remove ionic and non-ionic residues. This method is environmentally friendly compared to solvent-based cleaning and is often used in automated systems for high-volume manufacturing.

Process: PCBs are passed through a series of wash, rinse, and dry cycles using specialized equipment. Deionized water is typically used to prevent mineral deposits, ensuring a spotless, clear board. Studies show that aqueous cleaning can reduce ionic contamination by up to 90%, significantly improving reliability.

4. Plasma Cleaning for Precision and Surface Preparation

Plasma cleaning is a high-tech method that uses ionized gas to remove organic contaminants and prepare the PCB surface for processes like conformal coating or wire bonding. It’s particularly useful in advanced manufacturing where precision is critical.

Benefits: This method can clean at a microscopic level, removing residues that other methods might miss. It also activates the surface, improving adhesion for subsequent coatings, which can enhance long-term performance in harsh environments.

5. Dry Cleaning with Compressed Air or Brushes

For light dust and debris, dry cleaning methods like compressed air or anti-static brushes can be effective. This approach is quick and doesn’t involve liquids, making it safe for moisture-sensitive components.

Tip: Always use filtered, dry compressed air to avoid introducing moisture or new contaminants. This method is best for pre-assembly cleaning or maintenance rather than post-soldering residue removal.

Choosing the Right Cleaning Method for Your Needs

Selecting the appropriate cleaning method depends on several factors, including the type of PCB, the contaminants present, and the production volume. For high-speed digital boards requiring precise impedance control (often around 50 ohms for differential pairs), ultrasonic or plasma cleaning might be necessary to ensure no residues interfere with signal integrity. For simpler designs, manual or dry cleaning could suffice.

Additionally, consider the environmental impact and cost. Aqueous cleaning systems, while eco-friendly, require significant investment in equipment, whereas manual cleaning is low-cost but labor-intensive. Balancing these factors is key to achieving manufacturing excellence without compromising on quality or budget.

Best Practices for PCB Cleaning in Manufacturing

To maximize the benefits of PCB cleaning and ensure consistent electronic performance, follow these best practices:

- Clean at Multiple Stages: Incorporate cleaning after soldering, before conformal coating, and during final inspection to catch contaminants early.

- Use Proper Tools: Opt for lint-free wipes, ESD-safe brushes, and high-purity cleaning agents to avoid introducing new contaminants.

- Test for Cleanliness: Use ionic contamination testing to measure residue levels. Industry standards often aim for less than 1.56 micrograms of NaCl equivalent per square centimeter for reliable performance.

- Handle with Care: Minimize direct handling of PCBs and use gloves to prevent oil and fingerprint contamination.

- Maintain Equipment: Regularly clean and calibrate cleaning machines to ensure consistent results, especially for ultrasonic and aqueous systems.

The Role of Cleanliness in Meeting Industry Standards

In electronics manufacturing, adhering to industry standards like IPC-A-610 (Acceptability of Electronic Assemblies) is non-negotiable. These standards specify cleanliness levels to ensure reliability, especially for critical applications like aerospace or medical devices. For instance, IPC guidelines recommend visual inspection and ionic testing to confirm that no visible residues or harmful contaminants remain on the board.

By maintaining a rigorous cleaning process, manufacturers can meet these standards, avoid costly rework, and build trust with clients who demand high-quality, reliable products.

How Clean PCBs Enhance Long-Term Performance

A clean PCB is a reliable PCB. Removing contaminants reduces the risk of failures over time, such as corrosion-induced open circuits or dendrite growth between conductive traces. For high-speed designs, cleanliness ensures stable signal transmission, maintaining speeds of several gigabits per second without interference.

Moreover, clean boards improve the effectiveness of protective coatings, which shield against moisture, dust, and temperature extremes. This is especially important for devices operating in harsh environments, where a single failure can have significant consequences.

Conclusion: Achieve Manufacturing Excellence with Effective PCB Cleaning

Effective PCB cleaning is more than a routine step; it’s a vital component of manufacturing excellence. By removing contaminants and ensuring a clear board, manufacturers can enhance electronic performance, reduce failure rates, and meet the highest industry standards. Whether you opt for manual cleaning, ultrasonic systems, or advanced plasma technology, the goal remains the same: deliver reliable, high-quality PCBs that power the world’s electronics.

At ALLPCB, we’re committed to supporting your journey toward manufacturing excellence. By integrating robust cleaning processes into your workflow, you can achieve superior results and build products that stand the test of time. Let’s work together to keep your PCBs clean and your electronics performing at their best.

ALLPCB

ALLPCB