When it comes to cleaning printed circuit boards (PCBs), choosing the right method can make all the difference in maintaining the performance and longevity of electronics. Aerosol sprays and other spray methods are popular choices for removing contaminants like dust, flux residues, and grease. But which is better for your PCB cleaning needs? In short, aerosol sprays are often preferred for their precision and ease of use, while other spray methods, such as pump sprays or trigger sprays, may offer cost-effectiveness and versatility for larger areas. This blog dives deep into the comparison, exploring best practices, tools, and techniques to ensure your PCBs stay clean and functional.

Why Cleaning Printed Circuit Boards Matters

Printed circuit boards are the heart of most electronic devices, and over time, they can accumulate contaminants like dust, dirt, flux residues from soldering, and even corrosion from environmental exposure. These contaminants can interfere with electrical connections, cause short circuits, or degrade components, leading to device failure. Studies suggest that up to 30% of electronic failures can be attributed to poor cleaning or maintenance of PCBs. Proper cleaning not only extends the lifespan of electronics but also ensures consistent performance, especially in high-reliability applications like aerospace or medical devices.

Understanding Aerosol Sprays for PCB Cleaning

Aerosol sprays are pressurized cans that deliver a fine mist of cleaning solution, often a solvent like isopropyl alcohol or specialized electronics cleaners. They are widely used in PCB maintenance due to their convenience and targeted application. Here's why aerosol sprays stand out:

- Precision: Aerosol cans often come with a narrow nozzle or straw attachment, allowing users to direct the spray exactly where it's needed, minimizing waste and avoiding sensitive components.

- Consistency: The pressurized delivery ensures an even distribution of the cleaning agent, which can effectively dislodge contaminants from tight spaces on the PCB.

- Speed: Aerosol sprays dry quickly, often within seconds, reducing downtime during cleaning processes. For instance, a typical isopropyl alcohol-based aerosol can evaporate in under 10 seconds under normal conditions.

- No Residue: Many aerosol cleaners are formulated to leave no residue, which is critical for preventing new issues on the PCB after cleaning.

However, aerosol sprays have some drawbacks. They can be more expensive per use compared to other methods, and the cans may run out quickly during extensive cleaning tasks. Additionally, the propellants used in aerosols can be harmful to the environment if not disposed of properly.

Exploring Other Spray Methods for PCB Cleaning

Besides aerosols, other spray methods like pump sprays and trigger sprays are also used for cleaning printed circuit boards. These methods typically involve a manual pump or trigger mechanism to dispense liquid cleaners. Let's break down their features:

- Cost-Effectiveness: Pump or trigger sprays often come in larger containers, offering more cleaning solution for the price compared to aerosol cans. This makes them ideal for bulk cleaning tasks or larger PCBs.

- Versatility: These sprays allow users to control the amount of liquid dispensed, which can be useful for tackling stubborn contaminants that require more solvent or soaking.

- Environmentally Friendly: Unlike aerosols, pump sprays don't rely on propellants, making them a more eco-conscious choice for cleaning electronics.

On the downside, other spray methods may lack the precision of aerosols. The broader spray pattern can lead to overspray, potentially wetting areas of the PCB that should remain dry. They also tend to take longer to dry, as the application may result in more liquid being used. For example, a manual spray of isopropyl alcohol might take 20-30 seconds to evaporate fully, depending on the amount applied.

Comparing Aerosol vs Other Spray Methods: Key Factors

To decide which method suits your needs for cleaning PCBs, consider the following factors:

1. Application Precision

Aerosol sprays excel in precision due to their fine mist and targeted nozzles. This is crucial when working on small, densely populated PCBs where overspray could damage components. Pump sprays, while adjustable, often produce larger droplets, increasing the risk of liquid pooling in unwanted areas.

2. Cleaning Efficiency

Both methods can effectively remove contaminants, but aerosols often work faster due to their quick-drying nature. For instance, cleaning a PCB with an aerosol might take 2-3 minutes, while a pump spray could extend that to 5 minutes due to additional wiping or drying time.

3. Cost and Scalability

For small-scale or occasional cleaning, aerosols are convenient despite their higher cost per ounce. However, for larger operations or frequent maintenance, pump sprays offer better value with refillable bottles and bulk purchasing options.

4. Safety and Environmental Impact

Aerosols may pose inhalation risks due to propellants and require proper ventilation during use. They also contribute to waste through non-recyclable cans in some regions. Pump sprays, being propellant-free, are generally safer for both the user and the environment.

5. Compatibility with Contaminants

Both aerosol and other spray methods can handle common PCB contaminants like flux residues, dust, and light oils. However, for tougher residues, pump sprays might be more effective as they allow for heavier application and scrubbing if needed. Always check the cleaning solution's compatibility with your PCB materials to avoid damage.

Best Practices for Cleaning PCBs with Sprays

Regardless of whether you choose aerosol or another spray method, following best practices ensures safe and effective cleaning of printed circuit boards. Here are actionable tips to guide you:

1. Choose the Right Cleaning Solution

Select a cleaner specifically designed for electronics, such as isopropyl alcohol (at least 90% purity) or specialized solvent blends. Avoid water-based cleaners unless the PCB is rated for aqueous cleaning, as moisture can lead to corrosion or short circuits.

2. Work in a Ventilated Area

Cleaning sprays, especially aerosols, can release fumes that are harmful if inhaled. Always work in a well-ventilated space or under a fume hood to protect your health.

3. Power Off and Disconnect the Device

Before cleaning, ensure the electronic device is turned off and disconnected from any power source. This prevents electrical hazards and protects components from damage during the cleaning process.

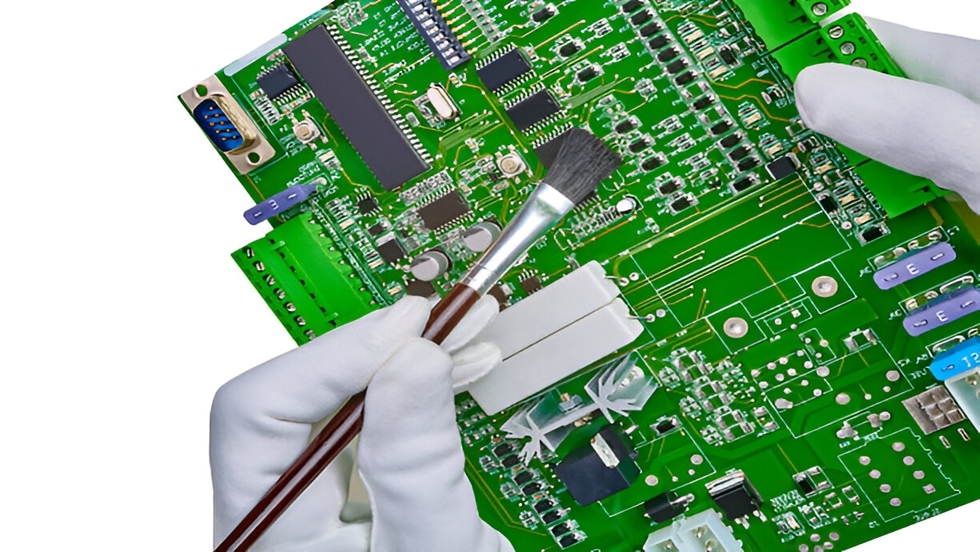

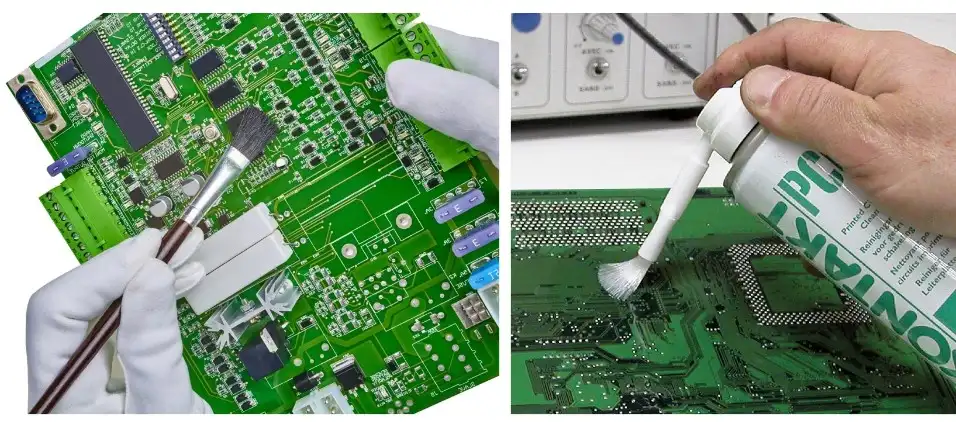

4. Use Proper Tools Alongside Sprays

Pair your spray with appropriate cleaning tools like soft-bristled brushes, lint-free cloths, or cotton swabs. For example, after applying an aerosol cleaner, use a brush to gently scrub away stubborn flux residues, then wipe with a microfiber cloth to remove excess liquid.

5. Test on a Small Area First

Before cleaning the entire PCB, test the spray on a small, non-critical area to ensure it doesn't damage components or strip away protective coatings. This is especially important with aggressive solvents.

6. Avoid Over-Spraying

Apply the spray sparingly to prevent liquid from pooling under components or in connectors. Excess liquid can take longer to dry and may cause issues like signal interference if not fully evaporated.

7. Allow Sufficient Drying Time

After cleaning, let the PCB air-dry completely before reassembling or powering on the device. Depending on the spray method, this could take anywhere from 10 seconds to a few minutes. Use compressed air to speed up drying if needed, but avoid high pressure that could dislodge components.

Additional Cleaning Tools for Enhanced Results

While sprays are essential for PCB cleaning, combining them with other tools can improve outcomes. Here are some complementary electronics cleaning tools to consider:

- Compressed Air: Useful for blowing away loose dust and debris before applying a spray. It helps prevent contaminants from being pushed deeper into the board during wet cleaning.

- Soft Brushes: Ideal for scrubbing away residues after spraying. Choose brushes with anti-static bristles to avoid static discharge that could harm sensitive components.

- Microfiber Cloths: These are perfect for wiping down the PCB after spraying, as they don't leave lint or scratches behind.

- Ultrasonic Cleaners: For deep cleaning, especially in industrial settings, ultrasonic cleaners can be used with appropriate solvents to remove contaminants from hard-to-reach areas.

Common Mistakes to Avoid When Cleaning PCBs

Even with the best spray methods, mistakes during cleaning can damage printed circuit boards. Here are pitfalls to steer clear of:

- Using Household Cleaners: Products not designed for electronics, like glass cleaners or disinfectants, can leave residues or damage components.

- Ignoring Static Electricity: Static discharge can fry sensitive components. Use anti-static wrist straps or work on an anti-static mat to ground yourself.

- Skipping Drying: Rushing to reassemble a device before the PCB is fully dry can lead to electrical shorts or corrosion over time.

- Overusing Solvents: Excessive use of cleaning sprays can degrade conformal coatings or labels on the PCB. Apply only as much as needed.

When to Choose Aerosol Over Other Sprays (and Vice Versa)

Deciding between aerosol and other spray methods depends on your specific needs:

- Choose Aerosol Sprays If: You need precision for small or intricate PCBs, are working on quick repairs, or prioritize fast drying times. They're ideal for hobbyists or small-scale projects.

- Choose Pump/Trigger Sprays If: You're cleaning larger boards, need to cover bigger areas, or are looking for a budget-friendly option for frequent use. They're better suited for industrial or bulk cleaning tasks.

Conclusion: Finding the Best Spray Method for Your PCB Cleaning

Cleaning printed circuit boards is a critical step in maintaining the reliability and performance of electronics. Aerosol sprays offer precision, speed, and convenience, making them a go-to choice for many technicians working on small or detailed tasks. On the other hand, other spray methods like pump or trigger sprays provide cost savings and versatility, especially for larger-scale cleaning operations. By understanding the strengths and limitations of each method, along with adhering to best practices, you can ensure your PCBs remain free of contaminants and function optimally.

Whether you're a hobbyist tinkering with a single board or a professional managing high-volume electronics production, selecting the right spray method and tools tailored to your needs is key. With the insights provided in this guide, you're equipped to make an informed decision and keep your electronics in top shape.

ALLPCB

ALLPCB