If you're looking for a cost-effective, environmentally friendly surface finish for your printed circuit boards (PCBs), OSP (Organic Solderability Preservative) might be the perfect choice. In this quick guide, we'll explain what OSP surface finish is, its benefits, limitations, and how it fits into PCB manufacturing. Whether you're an engineer, designer, or manufacturer, this blog will provide you with actionable insights to make informed decisions for your next project.

What Is OSP Surface Finish for PCBs?

OSP, or Organic Solderability Preservative, is a surface finish applied to the exposed copper traces and pads of a PCB. This organic coating acts as a protective layer, preventing the copper from oxidizing or corroding before soldering. Unlike metallic finishes, OSP is a thin, water-based organic compound that forms a chemical bond with the copper surface, ensuring the PCB remains solderable during assembly.

Introduced as a lead-free alternative to traditional finishes like HASL (Hot Air Solder Leveling), OSP has gained popularity due to its compliance with environmental regulations such as RoHS (Restriction of Hazardous Substances). It is widely used in consumer electronics, automotive, and industrial applications where cost and eco-friendliness are key considerations.

Why Choose OSP Surface Finish? Key Benefits

OSP offers several advantages that make it a preferred choice for many PCB applications. Let's dive into the specific benefits that set it apart from other surface finishes.

1. Cost-Effectiveness

One of the standout features of OSP is its low cost. The materials used in the OSP process are simple chemical compounds, and the application process doesn't require complex equipment or additional steps. This makes OSP significantly cheaper than alternatives like ENIG (Electroless Nickel Immersion Gold), which involves multiple plating processes. For high-volume production, choosing OSP can lead to substantial savings without compromising quality.

2. Environmentally Friendly

OSP is a green solution in PCB manufacturing. Since it uses a water-based organic compound, it avoids the use of heavy metals or harmful chemicals often found in other finishes. This aligns with global environmental standards, making OSP an ideal option for projects that need to meet strict regulatory requirements.

3. Excellent Solderability

The organic layer in OSP provides good wettability, meaning solder adheres well to the copper surface during assembly. When flux is applied, it easily penetrates the OSP coating to reach the copper underneath, ensuring strong and reliable solder joints. This makes OSP particularly suitable for surface-mount technology (SMT) processes, where precise soldering is critical.

4. Easy Rework and Repair

Unlike some metallic finishes that are difficult to rework, OSP-coated PCBs can be easily repaired or recoated if the protective layer is damaged. This flexibility is a major advantage for manufacturers who need to make adjustments during production or after assembly.

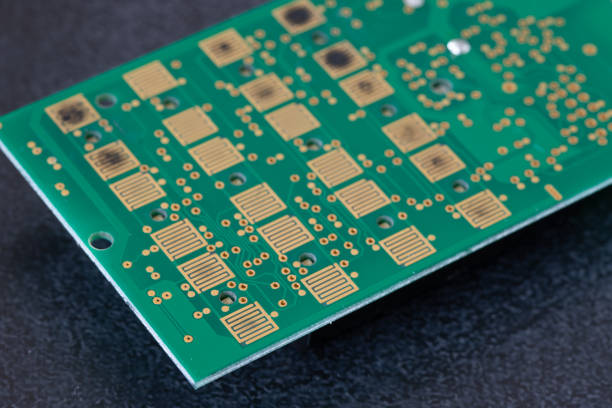

5. Flat Surface for Fine-Pitch Components

OSP provides a very flat surface, which is essential for mounting fine-pitch components. Unlike HASL, which can create uneven surfaces due to solder bumps, OSP ensures consistent pad geometry. This flatness is crucial for modern electronics with tight tolerances, such as smartphones or wearable devices, where components are densely packed.

Limitations of OSP Surface Finish

While OSP has many benefits, it's not a one-size-fits-all solution. Understanding its limitations can help you decide if it's the right choice for your specific application.

1. Limited Shelf Life

OSP has a shorter shelf life compared to other finishes like ENIG or immersion tin. The organic coating can degrade over time, especially if exposed to high humidity or temperature fluctuations. Typically, OSP-coated PCBs should be assembled within 6 to 12 months to ensure optimal solderability. Proper storage in a controlled environment can extend this period slightly, but it's still a consideration for long-term projects.

2. Sensitivity to Handling

The organic layer in OSP is delicate and can be easily damaged by fingerprints, scratches, or contamination. This sensitivity requires careful handling during manufacturing and assembly. Workers often need to wear gloves to avoid leaving oils or residues on the PCB surface, which could affect solderability.

3. Not Suitable for Multiple Reflow Cycles

OSP is less durable during multiple reflow soldering processes. The organic coating can break down after one or two reflow cycles, reducing its effectiveness. For complex assemblies requiring multiple soldering steps, a more robust finish like ENIG might be a better choice.

4. Limited Protection Against Harsh Environments

While OSP protects copper from oxidation under normal conditions, it offers limited resistance to harsh environments with high humidity, extreme temperatures, or corrosive elements. For applications in industrial or outdoor settings, additional protective measures or a different surface finish may be necessary.

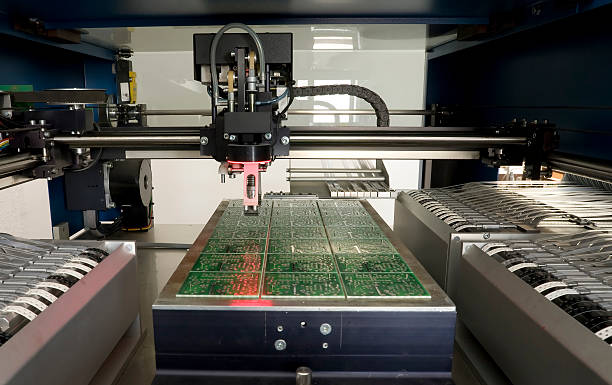

How Is OSP Applied in PCB Manufacturing?

The OSP application process is straightforward, which contributes to its cost-effectiveness. Here's a step-by-step overview of how it's done during PCB fabrication.

- Cleaning: The PCB surface is thoroughly cleaned to remove any contaminants, oils, or oxides from the copper traces and pads. This step is critical to ensure proper adhesion of the OSP coating.

- Micro-Etching: A mild etching solution is applied to create a slightly rough surface on the copper. This improves the bonding between the copper and the organic compound.

- OSP Coating: The PCB is immersed in a solution containing the organic compound, typically an azole-based material. This forms a thin protective layer (about 0.2 to 0.5 microns thick) over the copper.

- Rinsing and Drying: The board is rinsed to remove excess solution and then dried to complete the process.

The simplicity of this process means it can be easily integrated into standard PCB manufacturing workflows without requiring specialized equipment.

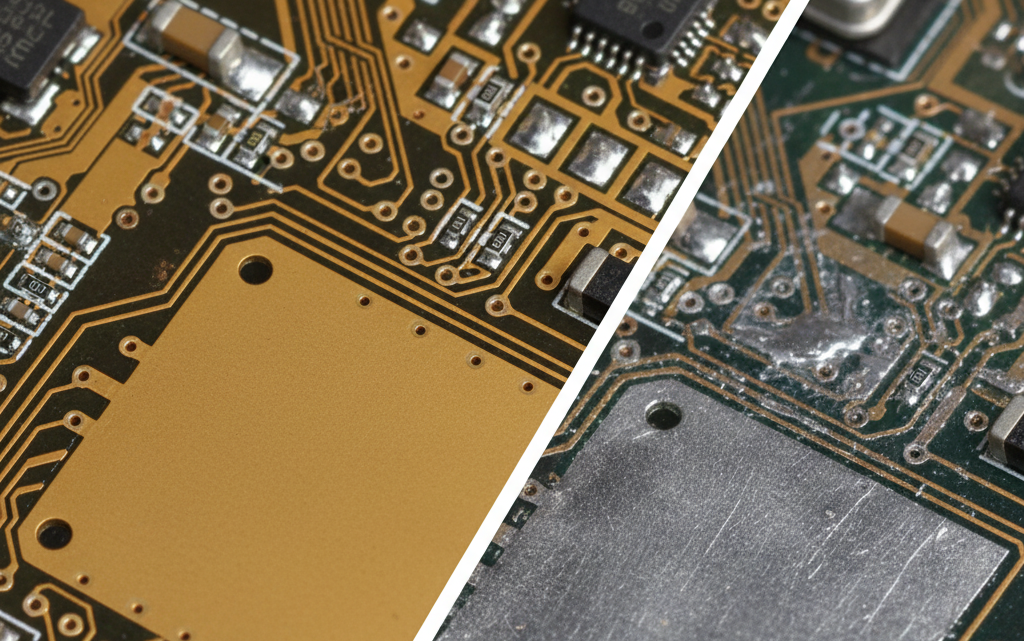

OSP vs. Other Surface Finishes: A Comparison

To better understand where OSP fits in, let's compare it to two other common surface finishes based on key parameters like cost, durability, and application suitability.

| Parameter | OSP | ENIG | Immersion Tin |

|---|---|---|---|

| Cost | Low | High | Medium |

| Shelf Life | 6-12 months | 12+ months | 12 months |

| Solderability | Good | Excellent | Good |

| Environmental Impact | Low (Eco-Friendly) | Medium | Medium |

| Suitability for Fine-Pitch | Excellent | Excellent | Good |

From the table, it's clear that OSP excels in cost and environmental impact but falls short in shelf life and durability compared to other finishes. Your choice will depend on the specific needs of your project, such as budget constraints or environmental conditions.

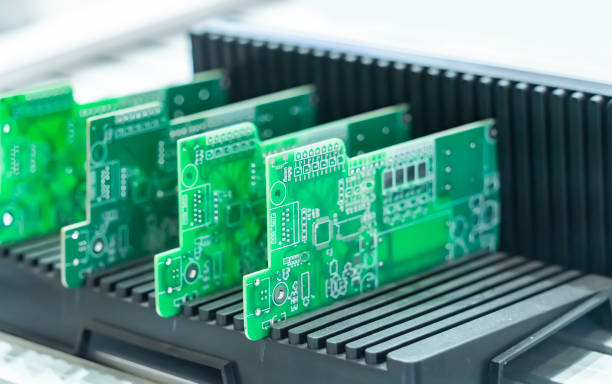

Best Applications for OSP Surface Finished PCBs

OSP is not a universal solution, but it shines in specific scenarios. Here are some of the best applications where OSP surface finished PCBs perform exceptionally well.

- Consumer Electronics: Devices like smartphones, tablets, and wearables often use OSP due to its flat surface for fine-pitch components and low cost for high-volume production.

- Automotive Electronics: For non-critical components in controlled environments, OSP provides a cost-effective and eco-friendly option.

- Short-Term Storage Projects: If your PCBs will be assembled within a few months, OSP's limited shelf life won't be an issue, making it a practical choice.

- Single Reflow Assemblies: Projects that require only one soldering cycle can benefit from OSP's good solderability without worrying about coating degradation.

Tips for Working with OSP Surface Finished PCBs

To get the most out of OSP, follow these practical tips during design, manufacturing, and assembly stages.

- Store Properly: Keep OSP-coated PCBs in a cool, dry environment, ideally in vacuum-sealed packaging, to extend shelf life and prevent degradation of the organic layer.

- Minimize Handling: Use gloves when handling OSP PCBs to avoid contamination from skin oils or dirt, which can compromise solderability.

- Plan Assembly Timeline: Schedule assembly within the recommended shelf life of 6 to 12 months to ensure optimal performance.

- Use Appropriate Flux: Choose a flux that is compatible with OSP to ensure proper wetting and strong solder joints during assembly.

Conclusion: Is OSP Right for Your PCB Project?

OSP surface finish offers a unique combination of cost-effectiveness, environmental friendliness, and excellent solderability, making it a strong contender for many PCB applications. However, its limitations, such as a shorter shelf life and sensitivity to handling, mean it's not suitable for every project. By understanding its strengths and weaknesses, you can decide if OSP aligns with your design requirements, budget, and timeline.

At ALLPCB, we're committed to helping you choose the best surface finish for your PCBs. Whether you opt for OSP or another solution, our team is ready to support you through every step of the manufacturing process with high-quality services tailored to your needs.

If you're ready to start your next PCB project with OSP or have any technical specifications to discuss, reach out to us for expert guidance and reliable production solutions.

ALLPCB

ALLPCB