Overview

Recent advances in flexible electronic materials and devices have accelerated wearable technologies, including implantable devices, electronic skin, and physiological signal monitoring. These developments enable continuous monitoring of human health and activity. For many applications, developing multifunctional flexible sensors with high sensitivity and low cost is essential. Among flexible sensors, epidermal electronic sensors that can accurately detect temperature and pressure changes are particularly important for health-monitoring systems.

Research summary

According to a report by Mems Consulting, researchers at the University of Science and Technology of China and the Institute of Metal Research, Chinese Academy of Sciences, have developed a flexible dual-parameter temperature-pressure sensor based on 3D spiral thermoelectric Bi-Te films. The Bi-Te films exhibit (000l) texture and good mechanical flexibility, with a Seebeck coefficient up to 181 μV K^-1 and a piezoresistive coefficient of about 9.2. The sensor shows very high thermoelectric temperature sensitivity (?426.4 μV K^-1) and a fast response time of ~0.95 s. In addition, due to the piezoresistive effect of the Bi-Te films, the sensor demonstrates strong pressure response performance with a sensitivity of 120 Pa^-1. This work achieves high-performance dual-parameter sensing using a single highly flexible material and was published in Nature Communications under the title "Flexible temperature-pressure dual sensor based on 3D spiral thermoelectric Bi-Te films."

Material mechanisms

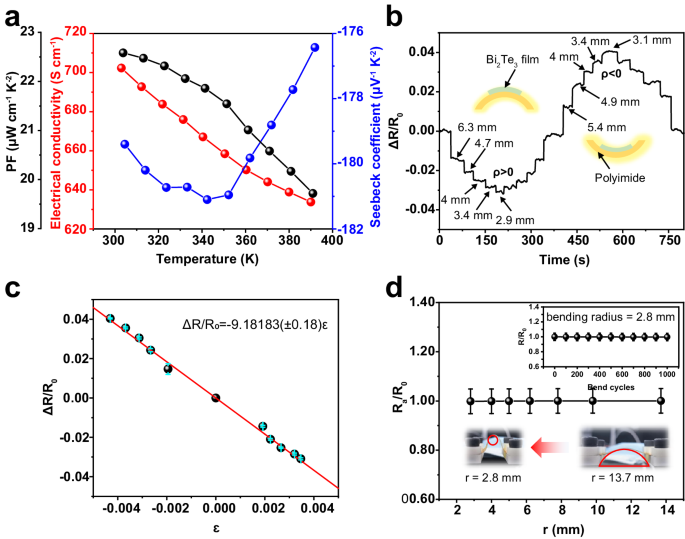

(000l)-textured Bi-Te is considered one of the most effective thermoelectric materials near room temperature. It exhibits both piezoresistive and thermoelectric effects, making it suitable for pressure and temperature sensing. These effects may originate from strain-induced changes in interlayer spacing that alter the bandgap. The 3D spiral architecture is a general structure applicable to thermoelectric films that can address issues of out-of-plane thermal resistance matching, offering new design possibilities. Combining Bi-Te films with a 3D spiral structure enables fabrication of high-performance temperature-pressure sensors. One limitation, however, is that when a hotter object contacts the sensor, the temperature at the sensor bottom surface can drift; therefore, bottom-surface temperature calibration is required to improve accuracy. Integrating a micro platinum (Pt) thin-film resistor to monitor the sensor bottom temperature or developing an appropriate mathematical model are effective solutions to this issue.

Device design and performance

In the reported work, the team deposited (000l)-textured Bi-Te films on a polyimide (PI) substrate to fabricate the temperature-pressure sensor. The Bi-Te films achieve a Seebeck coefficient of up to 181 μV K^-1, an electrical conductivity of approximately 700 S cm^-1, and a room-temperature power factor of 22.6 μW cm^-1 K^-2. The (000l) texture also yields a piezoresistive coefficient of about 9.2. These properties allow the device to detect temperature via thermoelectric voltage and pressure via resistance changes.

The researchers fabricated the 3D spiral structure using a custom femtosecond laser system and device-integration equipment to meet the out-of-plane thermal impedance requirements of applications such as temperature-sensing electronic skin. For pressure sensing, the spiral structure converts compressive deformation into device resistance fluctuations via the piezoresistive effect. By simultaneously monitoring voltage and resistance changes, the device achieves dual-parameter sensing of temperature and pressure.

Sensor array and practical testing

The team evaluated the flexible temperature-pressure sensor under various environmental conditions to verify its practical applicability. Considering the need for large-area, real-time spatial mapping of temperature and pressure in practical deployments, integration of sensor arrays is critical. Accordingly, the researchers fabricated an integrated 3 × 3 sensor-array electronic skin. Thanks to the Bi-Te films' thermoelectric performance and the 3D spiral design, the array can perform real-time temperature and pressure monitoring with fast and accurate responses.

Conclusions and prospects

This study demonstrates a straightforward and effective strategy for designing and fabricating high-performance temperature-pressure dual sensors by combining Bi-Te films with a 3D spiral architecture. Leveraging both the piezoresistive and thermoelectric effects of the Bi-Te films, the sensor responds rapidly to pressure and temperature changes; its large Seebeck coefficient yields high thermoelectric sensitivity (?426.4 μV K^-1). The 3D spiral design also significantly reduces response time (<1 s). The fabrication process is simple and produces a highly flexible sensor capable of accurate temperature mapping. The approach presents promising potential for integration into wearable systems such as electronic skin and related applications.

ALLPCB

ALLPCB