1. Cable Tray Wall Penetration Firestopping

1. Electrical cable tray wall penetration firestopping

- Scope: Firestopping for busway, cable trays, cables, and trunking passing through walls in enclosed electrical installations.

- Photograph

Core Procedures

- Where cables pass through shafts, walls, slabs, or enter electrical panels or cabinets, openings shall be tightly sealed with firestopping materials in accordance with design requirements.

- Process flow: reserved openings → busway installation → distribution box positioning and installation → conduit installation → cable routing → grounding → waterproof step → firestopping.

- Working conditions: floor and wall finishes in the electrical shaft completed, and shaft doors installed.

- Sealing shall be tight and reliable, without visible cracks or voids. For large openings, install a fire-resistant backing plate before sealing.

- Installation requirements:

- Layout and positioning must be reasonable to facilitate installation and maintenance.

- Choose appropriate fire protection materials, such as fire-rated board, firestop packs, firestop mastic, or fire-resistant mineral wool.

- Firestop packs should be placed in an orderly sequence. The gap area between firestop packs and cables should not exceed 1 cm2, and the packing thickness should be not less than 24 cm.

- All gaps inside and around metal trunking must be sealed tightly and be complete both internally and externally.

- Cover plates should be square, of consistent suitable dimensions, painted evenly, and used to close the opening.

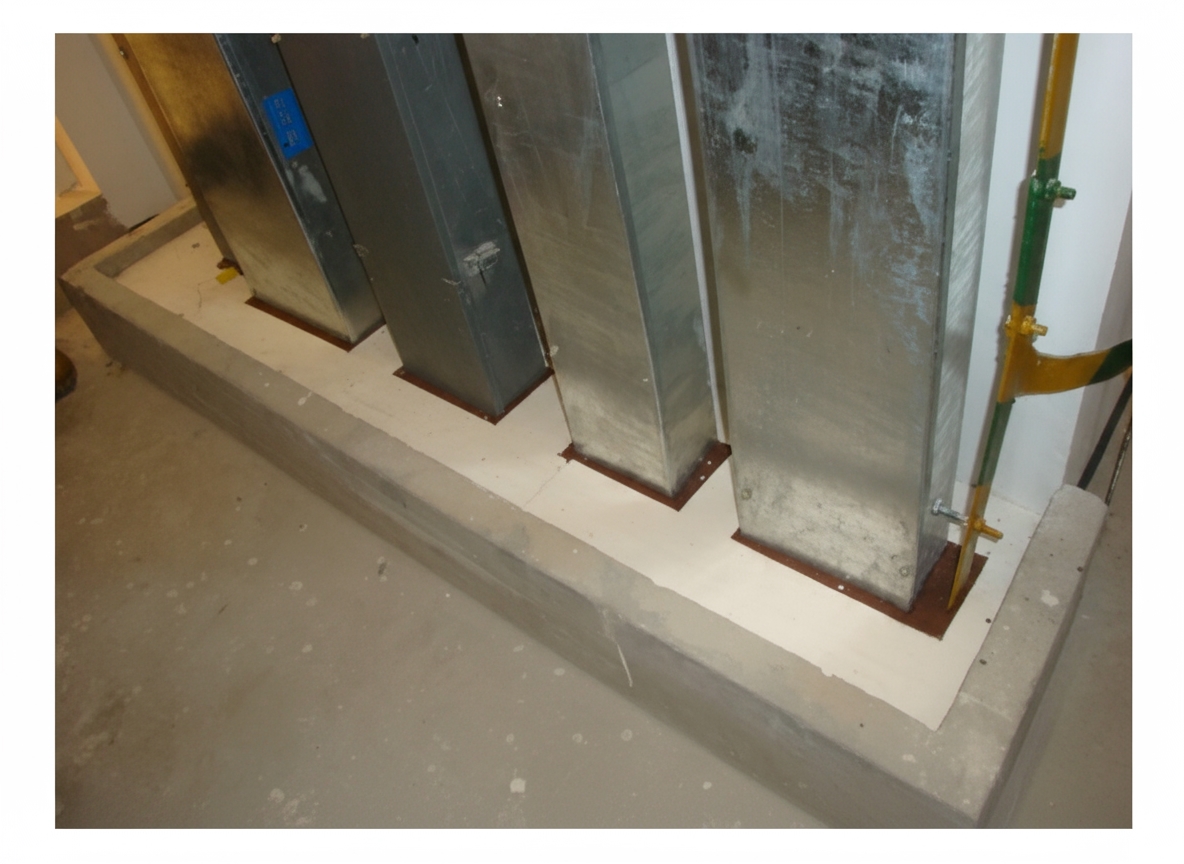

2. Firestopping at Slab Penetrations for Electrical Shafts

Scope: Firestopping for busway, cable trays, cables, and trunking where they pass through slabs in electrical shafts.

Photograph

Key Process Points

- Where cables pass through shafts, walls, slabs, or enter electrical panels or cabinets, openings shall be tightly sealed with firestopping materials in accordance with design requirements.

- An electrical shaft shall have a threshold. Cable trays and busways at floor level or at slab penetrations shall have a waterstop no less than 50 mm in height.

- At slab penetrations, provide 20–30 mm of firestopping and install a fire-support plate at the top.

- Sealing shall be tight and reliable, without visible cracks or voids. For large openings, install a fire-resistant backing plate before sealing.

- Installation requirements:

- Layout and positioning must be reasonable to facilitate installation and maintenance.

- Choose appropriate fire protection materials, such as fire-rated board, firestop packs, firestop mastic, or fire-resistant mineral wool.

- Firestop packs should be placed in an orderly sequence. The gap area between firestop packs and cables should not exceed 1 cm2, and the packing thickness should be not less than 24 cm.

- All gaps inside and around metal trunking must be sealed tightly and be complete both internally and externally.

- Cover plates should be square, of consistent suitable dimensions, painted evenly, and used to close the opening.

ALLPCB

ALLPCB