1. Laser Flying Welding

Laser flying welding combines long-range welding, galvo scanner technology, and robots, paired with specialized path-generation software to perform instantaneous multi-track welding in three-dimensional space. Typical applications include car bodies, seats, and common automotive components. Materials range from various steels and cold-rolled sheets to aluminum alloys and composite or alloy materials such as magnesium-aluminum alloys.

Advantages

- Any weld seam geometry

- Any weld seam orientation

- User-defined weld seam or spot distribution

- Optimized load distribution

- High-speed spot, seam, stitch, butt, fillet, and lap welding

- Real-time synchronization of the weld head and robot to accelerate the welding process

- Smaller footprint

- Lower maintenance and logistics costs

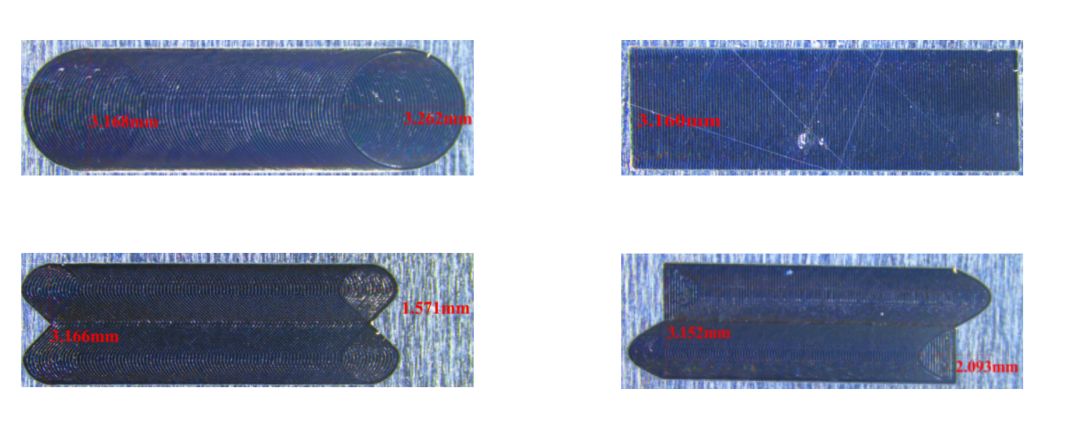

2. Spiral (Wobble) Welding

Spiral welding is a dual-wedge laser wobble welding method achieved by installing a dedicated wobble module on the weld head. The focused spot traces a helical path as the head moves, producing a spiral seam. Typical applications include hinge welding, heat exchangers, tubular heat exchangers, thick-pipe welding for oil and gas, flange welding, and aluminum alloy welding.

Spiral welding trajectory

Advantages

- Wider weld seam

- Very high process repeatability and stability

- Improved weld bead formation

- Simpler post-processing and smoother welded surfaces

- Excellent capability for aluminum alloy welding

3. Laser Brazing

Laser brazing uses a filler metal with a melting point lower than the base metal. The filler is heated above its melting point but below the melting temperature of the base material, allowing the liquid filler to wet the base material, fill the joint gap, and diffuse into the base material to form the connection. Typical applications include aluminum body frame structures, such as roof and side panel connections and doors.

Brazing principle

- Reduces defects typical of pure laser welding, such as porosity and cracking, and compensates for excessive part fit-up gaps

- Improves joint strength and achieves a smoother weld bead

- Base material does not melt; only the filler melts

- Low distortion, smooth and aesthetic joints; suitable for precise, complex, or dissimilar-material assemblies

- Small heat-affected zone and high compressive strength

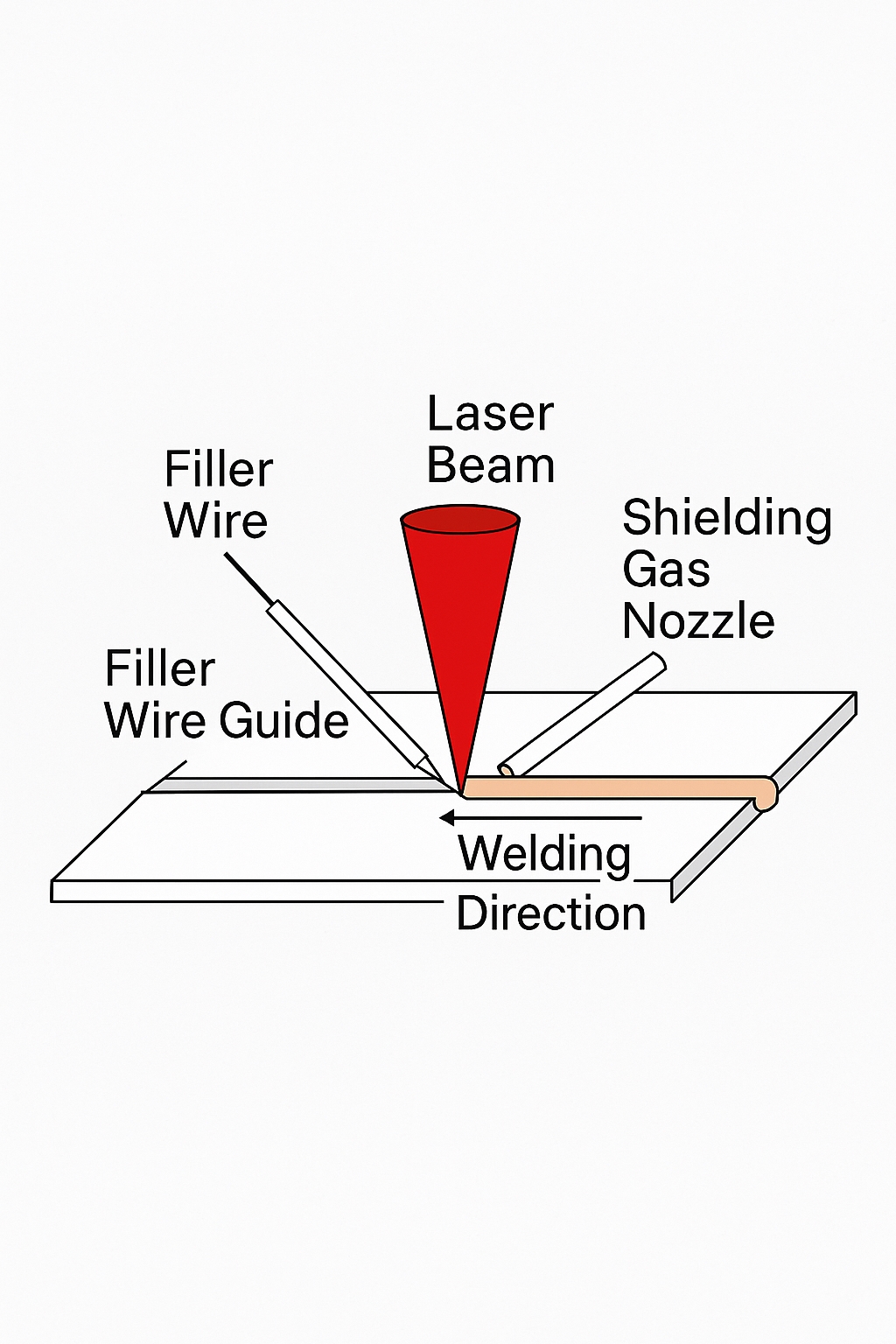

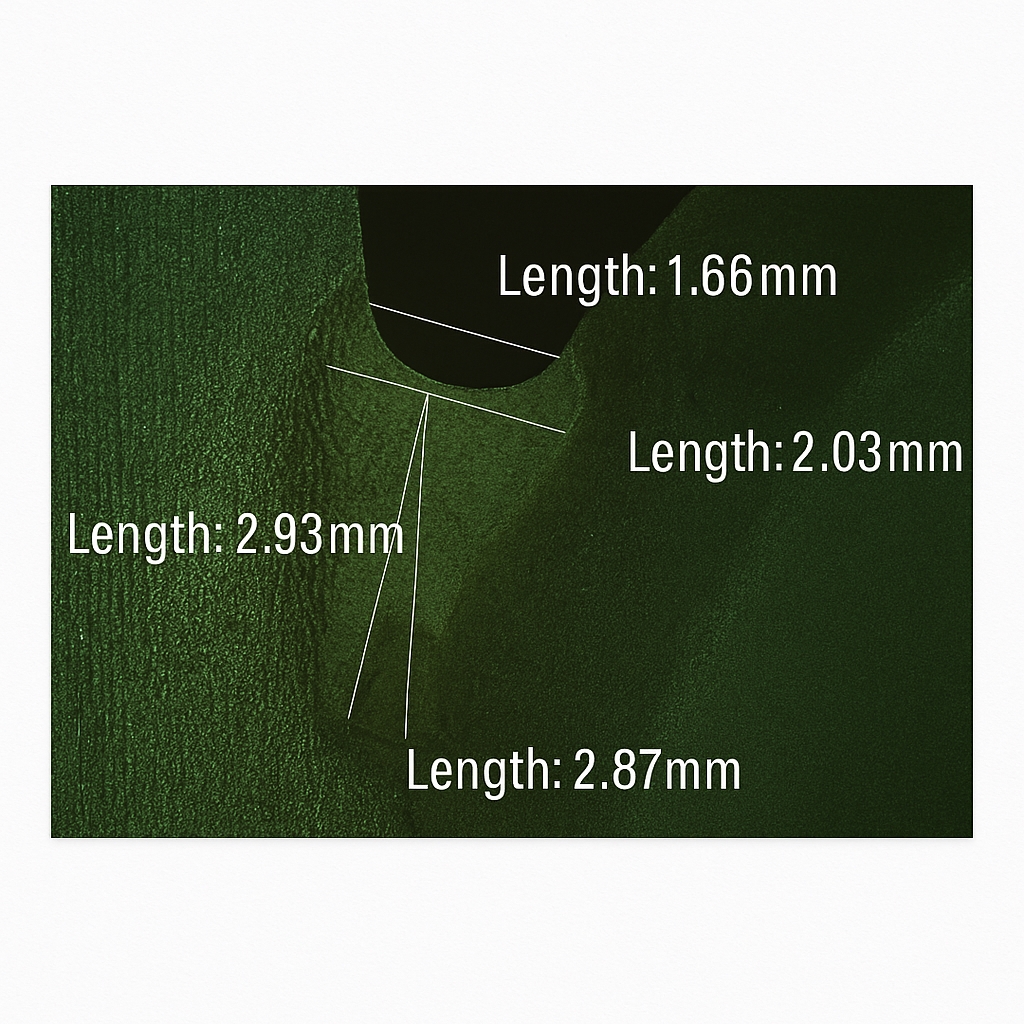

4. Laser Filler Welding

Laser filler welding melts the base material together with a filler metal of the same or similar composition, which solidifies to form the weld. Typical applications include full-vehicle structural components and automotive parts.

Weld microstructure

- Reduces defects like porosity and cracking associated with pure laser welding

- Improves yield by allowing larger part-fit gaps

- Base material melts; weld strength can exceed that of the base material

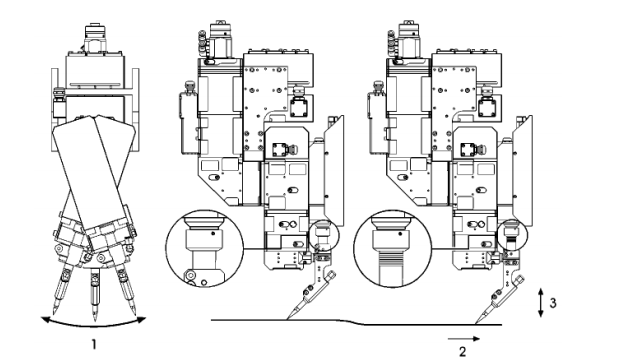

5. Oscillating Brazing

Oscillating brazing combines beam shaping and seam-tracking functions within one device. The filler wire can also act as a mechanical sensor. Typical applications are laser brazing in the body-in-white (BIW), including roof and trunk lid brazing and brazing of automotive components. Part variation and fixture errors often complicate laser brazing setup and process tuning. Oscillating brazing can automatically adjust weld direction, track seams, and compensate focal position, allowing the laser beam to be guided and focused across changing directions. This enables high automation, fast welding speed, and stable weld quality.

ALO3

- Seam tracking to determine the workpiece seam trajectory in real time

- XYZ three-axis adaptive adjustment of the welding path to accommodate part deviations and achieve consistent weld quality

- Improves weld consistency across products

6. Three-Spot Brazing

By adding a dual-spot module to the lens, a three-spot optical module splits a single beam into three beams during brazing. This provides a solution for brazing hot-dip galvanized steel, producing flatter, crack-free seams. Typical applications include aluminum brazing in the body-in-white, roof and trunk lid brazing, and brazing of automotive parts.

Advantages

- More stable and reliable brazing process

- Higher processing speed

- Higher joint strength

- Improved surface appearance for galvanized steel

- Inline cleaning capability

- Dynamic energy adjustment

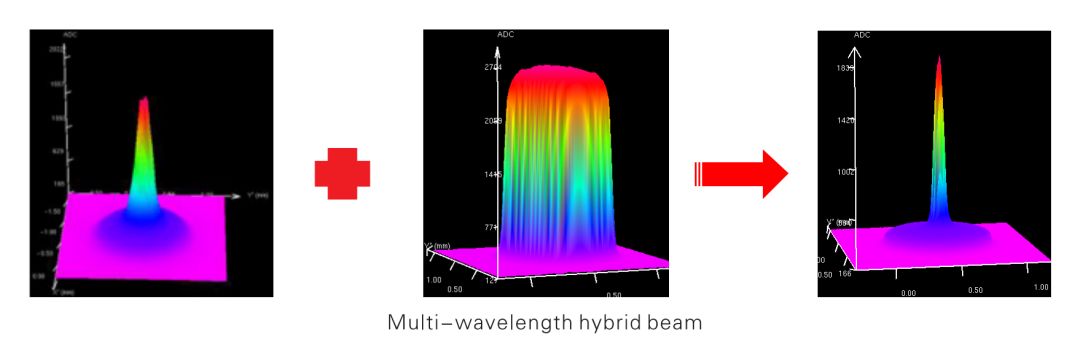

7. Multi-Wavelength Composite Welding

Multi-wavelength composite welding overlays two lasers of different wavelengths so their axes coincide spatially. The main wavelength performs welding while the secondary wavelength preheats the filler and base material, reducing the cooling rate of the molten pool. This approach is particularly suitable for aluminum, magnesium, and copper alloys.

Composite weld beam

- Reduces porosity

- Increases weld bead stability and welding efficiency

- Alleviates thermal stress, reducing cracking and improving weld strength and bead appearance uniformity

Summary

Overall, foreign technology and equipment still lead the laser industry in areas such as laser sources, optical processing heads, chillers, power meters, in-weld monitoring, post-weld inspection, and TCP calibrators. Companies in China are working to close this gap. In laser welding applications, the Chinese market has approached international levels, and several suppliers have achieved notable results.

ALLPCB

ALLPCB