Electrochemical migration (ECM) is a silent threat to the reliability of printed circuit boards (PCBs), leading to trace corrosion and potential circuit failure. If you're searching for ways to prevent PCB corrosion and protect your designs, you're in the right place. In this comprehensive guide, we'll explore what ECM is, how it causes issues like conductive anodic filament (CAF) growth, and actionable strategies such as PCB cleaning methods and conformal coating to safeguard your boards. Let's dive into the details to ensure your electronics remain reliable and long-lasting.

What Is Electrochemical Migration (ECM) and Why Does It Matter?

Electrochemical migration, often abbreviated as ECM, is a process where metal ions move across a PCB surface or through its substrate under the influence of an electric field, moisture, and ionic contaminants. This migration can form conductive paths, like dendrites, between traces, leading to short circuits or reduced insulation resistance. For engineers and manufacturers, ECM is a critical concern because it can cause catastrophic failures in electronic devices, especially in high-humidity or harsh environments.

The impact of ECM is significant. Studies have shown that it can reduce the surface insulation resistance (SIR) of a PCB from a safe level of over 10^9 ohms to a dangerous 10^6 ohms or lower in just a few hundred hours under accelerated testing conditions (65°C, 88% relative humidity, and DC bias). This drastic drop can disrupt signal integrity and lead to device malfunction, making PCB corrosion prevention a top priority.

Understanding the Causes of ECM and Conductive Anodic Filament (CAF)

To prevent ECM, it's essential to understand its root causes. The process typically occurs under specific conditions:

- Moisture Presence: A thin layer of water or electrolyte on the PCB surface acts as a medium for ion movement. High humidity environments (above 80%) significantly increase this risk.

- Voltage Bias: A direct current (DC) voltage between adjacent conductors drives the migration of metal ions. Even low voltages, such as 5V, can initiate ECM under the right conditions.

- Ionic Contaminants: Residues from flux, solder paste, or environmental pollutants (like NaCl from airborne dust) provide the ions necessary for migration.

- Material and Design Factors: The type of PCB finish (e.g., immersion silver or electroless nickel/immersion gold) and trace spacing play a role. Closer spacing, such as 12.5 mil versus 25 mil, heightens the risk of short circuits due to dendrite growth.

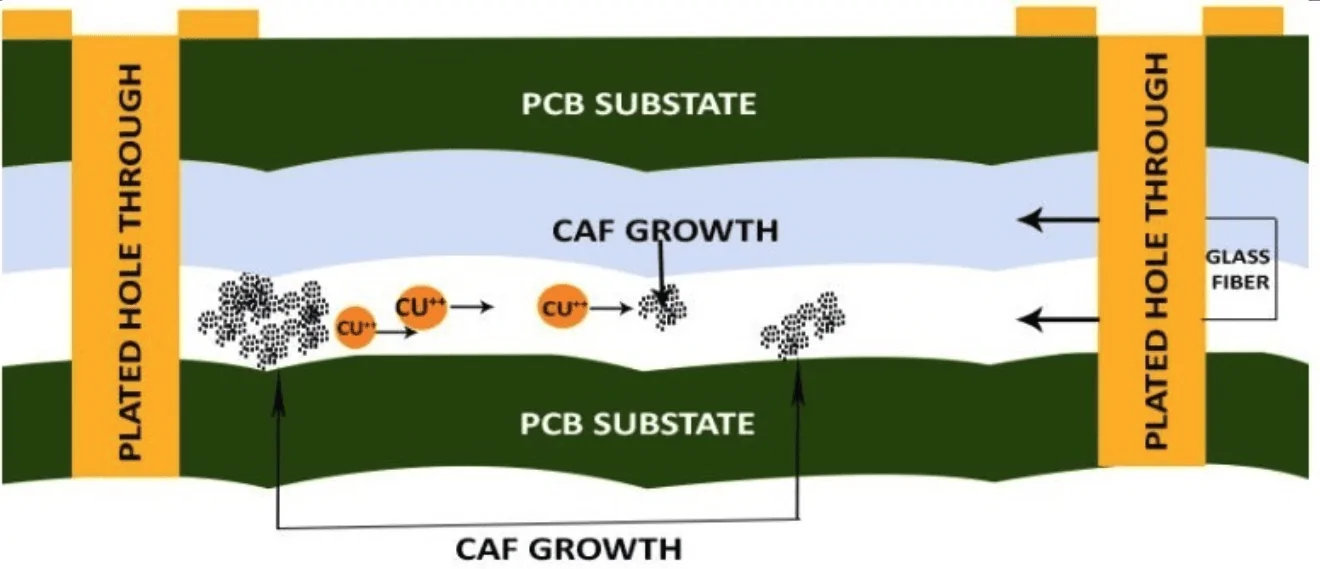

A related phenomenon is Conductive Anodic Filament (CAF), which occurs within the PCB substrate rather than on the surface. CAF forms when metal ions migrate along the glass fibers in the laminate, often due to poor material quality or manufacturing defects. This can create conductive paths between layers or vias, leading to failures that are harder to detect than surface ECM.

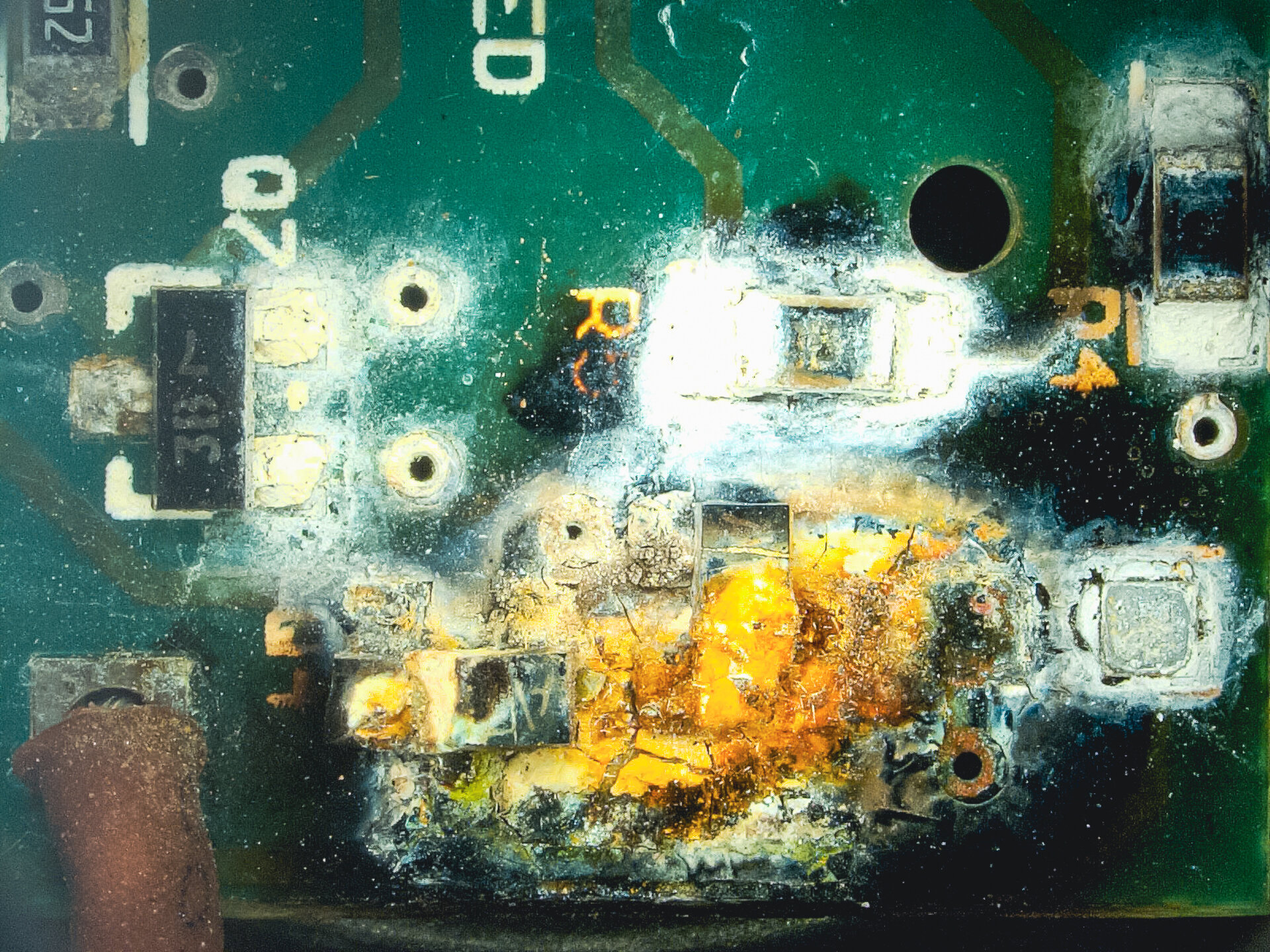

The Consequences of Ignoring ECM in PCB Design

Neglecting ECM can have dire consequences for electronic products. Short circuits caused by dendritic growth can lead to intermittent failures or complete device shutdowns. For critical applications like medical devices or automotive electronics, such failures can be life-threatening or result in significant financial losses.

Beyond immediate failures, ECM also accelerates corrosion of traces, weakening the structural integrity of the PCB. Over time, this corrosion can increase impedance in signal paths, affecting performance. For instance, a corroded trace might see its resistance rise from a nominal 0.1 ohms to several ohms, disrupting high-speed signals that require consistent impedance for integrity.

The cost of ECM-related failures isn't just in repairs or replacements. It can damage a company's reputation, especially if products fail in the field. Proactive PCB corrosion prevention is not just a technical necessity; it's a business imperative.

Strategies for Preventing Electrochemical Migration

Preventing ECM and CAF requires a multi-faceted approach, addressing design, manufacturing, and environmental factors. Below are proven strategies to protect your PCBs from corrosion and migration issues.

1. Optimize PCB Design for ECM Resistance

Design choices play a crucial role in minimizing ECM risks. Consider the following:

- Increase Trace Spacing: Wider spacing between conductors reduces the likelihood of dendrite bridging. While 12.5 mil spacing is common in compact designs, aim for 25 mil or more when possible to lower ECM risks.

- Select Appropriate Finishes: Surface finishes like electroless nickel/immersion gold (ENIG) are less prone to migration compared to immersion silver (ImAg), which can tarnish and promote ion movement under humid conditions.

- Use High-Quality Laminates: Choose PCB materials with low moisture absorption and high resistance to CAF. Materials meeting IPC-4101 standards with low delamination risks are ideal.

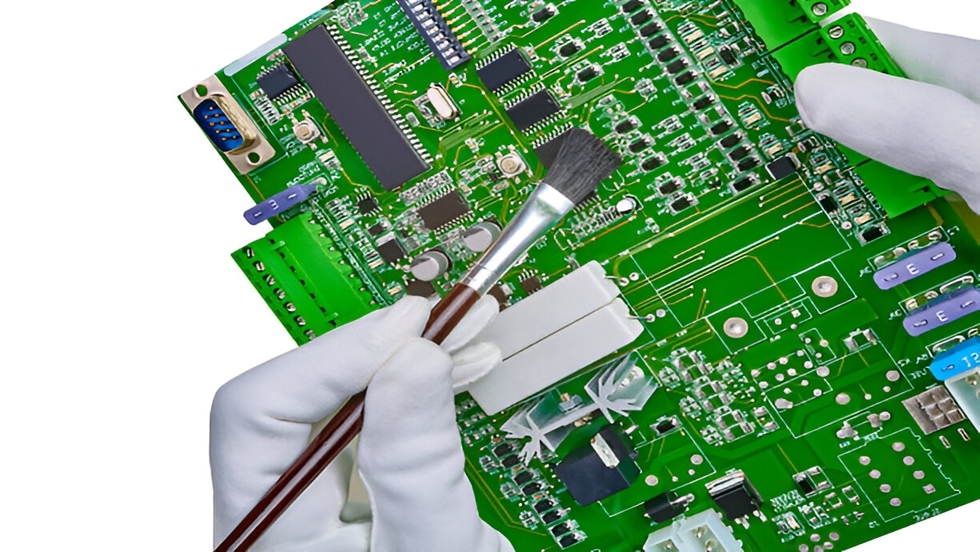

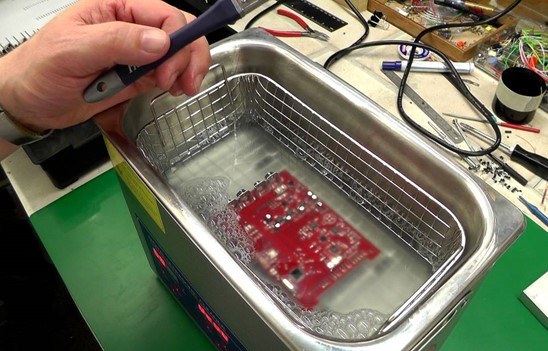

2. Implement Effective PCB Cleaning Methods

Residual contaminants are a primary driver of ECM. Thorough cleaning after manufacturing removes flux residues, solder paste, and other ionic materials that could facilitate migration. Here are key PCB cleaning methods:

- Aqueous Cleaning: Use deionized water with specialized detergents to wash away residues. Ensure the water resistivity is above 10 MΩ·cm to avoid introducing new contaminants.

- Ultrasonic Cleaning: This method uses high-frequency sound waves to dislodge stubborn residues from tight spaces. However, use it cautiously as excessive power can damage delicate components.

- Plasma Cleaning: A dry cleaning process that uses ionized gas to remove organic contaminants. It's highly effective for critical applications but requires specialized equipment.

After cleaning, test for ionic contamination using methods like ion chromatography to ensure residues are below acceptable limits (typically less than 1.56 μg/cm2 of NaCl equivalent per IPC-TM-650 standards).

3. Apply Conformal Coating for PCB Protection

Conformal coating is a protective layer applied to PCBs to shield them from moisture, dust, and contaminants. It's one of the most effective ways to prevent ECM in harsh environments. Here's what you need to know about conformal coating for PCB protection:

- Types of Coatings: Common options include acrylic, silicone, polyurethane, and epoxy. Silicone coatings are ideal for high-humidity environments due to their moisture resistance, while acrylics are easier to rework.

- Application Methods: Coatings can be applied via brushing, spraying, or dipping. Automated selective coating machines ensure even application with thicknesses typically between 25 to 75 microns.

- Benefits: A well-applied conformal coating can reduce the risk of ECM by up to 90% in humid conditions by preventing moisture from reaching the PCB surface.

Ensure that the coating adheres to standards like IPC-CC-830 for qualification and performance. Also, avoid coating over areas like connectors or test points unless specified, as it can interfere with functionality.

4. Control Environmental Factors

Even with the best design and cleaning practices, environmental conditions can still trigger ECM. Take these steps to minimize risks:

- Humidity Control: Store and operate PCBs in environments with relative humidity below 60%. Use desiccants or climate-controlled storage for sensitive boards.

- Temperature Management: High temperatures accelerate corrosion and migration. Keep operating temperatures below 85°C to reduce stress on materials.

- Minimize Contaminant Exposure: Protect PCBs from airborne pollutants like sulfur compounds or salt spray, especially in industrial or coastal areas.

5. Test and Monitor for ECM and CAF

Regular testing during development and production can catch potential ECM issues before they become failures. Use these methods:

- Surface Insulation Resistance (SIR) Testing: Measure the resistance between traces under high humidity and voltage bias (e.g., 40V at 65°C/88% RH) to detect early signs of migration.

- Accelerated Life Testing: Simulate harsh conditions to predict long-term reliability. A common test is 1000 hours at elevated temperature and humidity to observe dendrite growth or CAF formation.

- Microscopic Inspection: Use scanning electron microscopy (SEM) to visually inspect for dendritic growth or internal filament formation in the substrate.

Case Study: ECM Failure in High-Humidity Environments

Consider a real-world scenario where ECM caused failure in a batch of PCBs used in outdoor industrial sensors. The boards, designed with immersion silver finish and tight 12.5 mil trace spacing, were exposed to 90% relative humidity and temperatures averaging 40°C. Within six months, over 30% of the units failed due to short circuits caused by dendritic growth between traces.

Analysis revealed high levels of ionic contamination from flux residues left after assembly. The solution involved switching to an ENIG finish, increasing trace spacing to 20 mil, implementing rigorous aqueous cleaning, and applying a silicone-based conformal coating. Post-implementation, failure rates dropped to under 2% over the next year, demonstrating the effectiveness of combined PCB corrosion prevention strategies.

Conclusion: Safeguard Your PCBs Against ECM

Electrochemical migration is a formidable challenge for PCB reliability, but with the right approach, you can prevent trace corrosion catastrophes. By optimizing design, using effective PCB cleaning methods, applying conformal coating, controlling environmental factors, and conducting thorough testing, you can significantly reduce the risks of ECM and CAF. These steps not only protect your boards but also ensure the longevity and performance of your electronic products.

At ALLPCB, we’re committed to helping engineers and manufacturers achieve reliable, high-quality PCB solutions. Whether you're tackling a complex design or scaling up production, implementing these strategies will keep your projects safe from the hidden dangers of corrosion and migration.

ALLPCB

ALLPCB